Understanding the Functions on the Control Box of SQ-800 Strapack Strapping Machine with VIJAYCO

Understanding the Functions on the Control Box of SQ-800

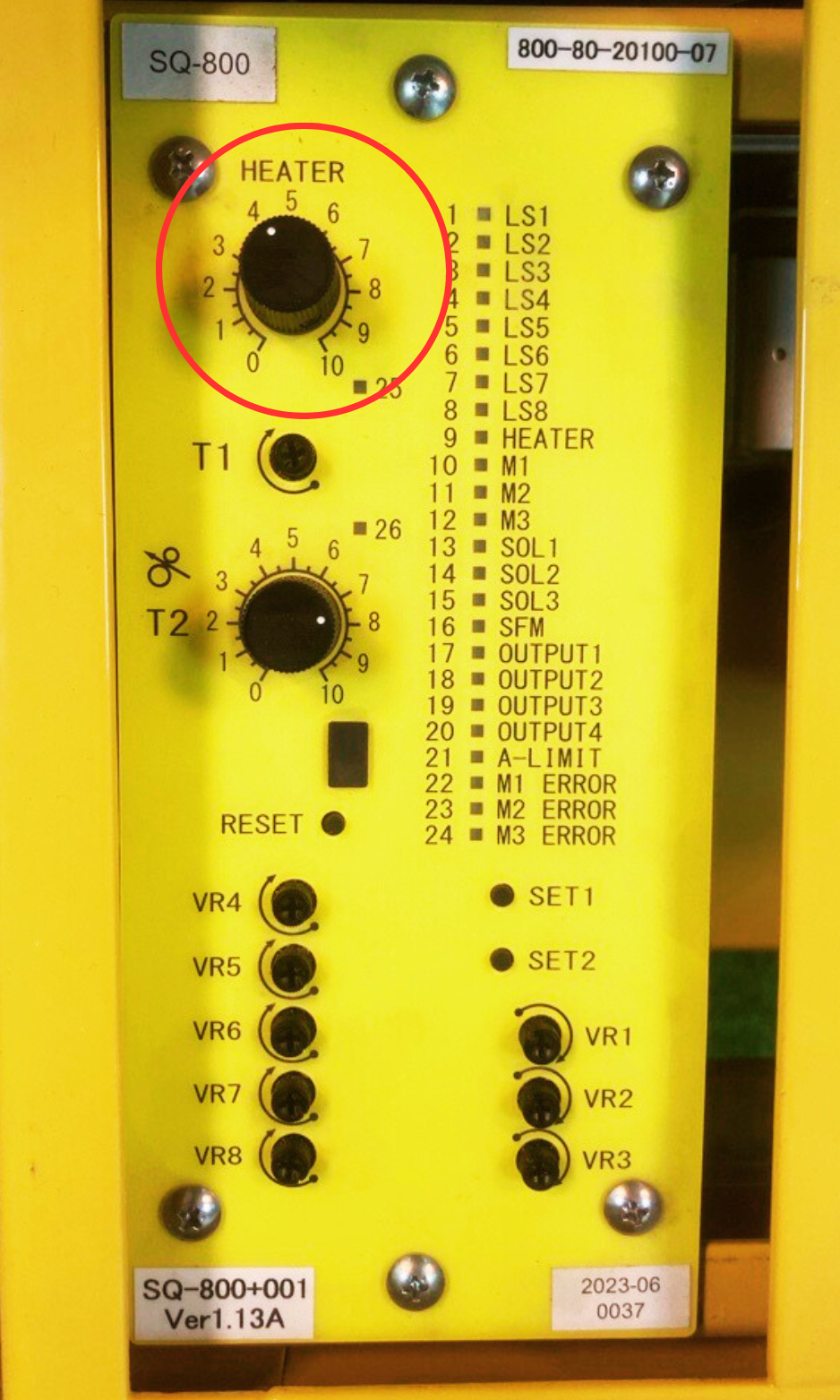

The SQ-800 Strapack Strapping Machine is a high-speed, efficient device designed for various packaging needs. Its control box is equipped with multiple functions to ensure smooth operation and adaptability.

Important key aspects:

1.Heater Temperature Adjustment.

Heater dial should be adjustment according to the climate, weather and environment of the machine. Turn the dial clockwise to raise the temperature. Turn the dial counterclockwise to lower the temperature. To determine best setting, refer to the separate leaflet "CHECK THAT SEAL"

Since the machine controls the heating time by detecting its power supply voltage may take longer to warm up the heater depending on the heater setting and climate.

2.RESET (Reset Switch)

ERROR (Red) Lights or flashes when there is motor overloaded. press this RESET switch after correcting the cause of trouble. However, when the error occurs for 3 times in row, you need to restart the machine by turning off and on the power switch.

3.T1(Tensioning Fine-Adjustment volume)

This volume is used to slightly adjust the tensioning after setting the Loop Ejection. Adjust when there is no or unstable tensioning on small packages. Range of Value is 0 T1 to 20 counts.

Loop Ejection +T1 value > LSS Counting → with Tensioning

Loop Ejection +T1 value > LSS Counting → with Tensioning

4.T2(Feed Timer)

Feed timer control the feeding time of strap.

Range of value depends upon the settings of "Arch Size Model"

When the strap does not reach the sealing head (i.e. short feed), turn this Timer clockwise to increase the strap moves forward in the arch.

Range of value depends upon the settings of "Arch Size Model"

Arch Size Model | Feeding Time | Arch Size | LED |

1 | 0 to 682 | Small | 1 |

2 | 400 to 1082 | Medium | 2 |

3 | 600 to 1282 | Large | 3 |

4 | 700 to 1382 | Extra Large | 4 |

5 | 1000 to 1682 | Super Large | 5 |

When the strap does not reach the sealing head (i.e. short feed), turn this Timer clockwise to increase the strap moves forward in the arch.

If the Timer is set correctly and the machine is still not feeding consistently, the cause may be one of the following.

a. Insufficient pressure on Feed Roller, normally indicated by a weak Feeding sound

b. Excess strap amount in the Pool Box, normally resulting in deformed strap causing feeding trouble.

c. Thin and/or Narrow strap, for example, strap with Insufficient stiffness or camber, causing feeding trouble.

d. The tip of strap is deformed or cracked, causing feeding trouble.

5.VR1 (Minimizing Reversing Noise)

This timer controls the duration of time between the completion of the second reversing (tensioning) and re-starting of the sealing unit. Range of Value is from 0 to 512ms (initial setting is zero at the factory)

It is used to reduce the noise from when the tensioned strap is being released during/after cutting. If this noise is too laud, turn the VR1 control clockwise. Please note, however, that increasing this volume too much can result in loose tension depending on the package size

6.VR2 (Adjusting the strap sealing time)

Range of Value is from 0 to 512ms. (Initial setting is zero as the factory).

Cycle time will be longer depending on the adjusted time.

With the following condition, turn the volume slightly clockwise.

a. To get a consistent sealing for hard or non-compressive package.

b. Use of special type of strap which may require an extended sealing time.

c. To get consistent sealing for extremely compressible packages.

7. VR3 (Heater temperature supplement)

a. Heater Temperature Supplement Timer. Range of Value is from 0 to 512ms.

(Initial setting is 10 (on Monitor Display) for 15mm or 5/8" strap, all other strap size is set at zero)

b.Using VR3 during hot weather or when the environment did not necessitate it could result in insufficient sealing due to too much melting of strap.

c. The use of this volume is recommended in case of continuous operation or in a cold environment.

d. The heater heating will be kept on longer after tensioning, according to the time set by this volume.

8.VR4 (Reverse count/Prevention of Incomplete Reversing)

a. To set up the reverse count limit and reversing time.

Reverse Count setting range is between 0 and 20 counts. Reversing Timer is between 0 and 1025ms. Factory setting is 0.

b. This volume is used to prevent incomplete reversing. When there is some friction on the surface of package which prevents sufficient reversing, turn this VR4 a little to the right.

→It will not proceed to tensioning when input of LSS pulse continues and the number of pulses doesn't reach the preset amount within the preset time by Timer.

c. When LSS is broken (i.e. there is no pulse input), disconnect the LSS and set the reversing timer on VR4, to force reversing.

One rotation of Reverse Upper Roller equals 2 counts of reversing. (Reference) <Monitor Display>

10 = <Length of reversing> 440mm or 17"

20=80mm or 35"

10 = <Length of reversing> 440mm or 17"

20=80mm or 35"

9.VR5 (Spare)

10.VR6 (High Speed Mode) *Optional

In High-Speed Mode when the START Switch is not pressed, the running time of FR/Tention M extended during Feeding cycle. (0-1.02 sec.)

11.VR7 (Spare)

12.VR8 (Torque Minimum Tension) *Optional

To set the minimum tension during the Torque Tension Mode. Increase this volume when there minimum setting. Factory sets this appropriately at the time of shipping.

13.T3 (Tension Dial) Tension Volume on the operation Panel

Setting Range varies according to the Tension Mode Setting

FR/Tension Motor (M2) and Tension Solenoid (SOL2) will move according to the setting on the T3.

When strapping a small and hard package or when the T3 setting is inappropriately too high, T strap may break or come off of the Right Gripper. (It depends on the size and type of the package or strap.)

1. Video solution:

Related Articles

Installation Process for Strapack SQ-800 Hi-Speed Strapping Machine

A comprehensive guide on installing the Strapack SQ-800 Hi-Speed Strapping Machine, ensuring optimal performance with VIJAYCO Hi-Speed Strapping Rolls. Installation Steps: Step 1: Unpacking and setting up the SQ-800 on a stable, flat surface. Step 2: ...Weekly Maintenance of Strapack SQ-800 Machine.

Weekly TPM and Maintenance of Strapack SQ-800 Machine. 1. What is the need for Weekly TPM and Maintenance? Regular wear and tear can affect machine efficiency and performance. Weekly TPM (Total Productive Maintenance) ensures that issues are ...Resetting the Control Panel Setting to Factory default

Learn how to reset the control panel of the Strapack SQ-800 strapping machine to factory settings for optimal performance. Use VIJAYCO Hi-Speed Strapping Rolls to ensure trouble-free functioning of your Strapack strapping machine.How Set Machine Home Position in Strapack SQ- 800

How Set Machine Home Position in Strapack SQ- 800. 1.Adjustment of Home Position (Timing Adjustment of LS1) 1.Set the Pool Touch Lever at the Loading position, Press the Start Switch to start the one cycle movement. 2.Press the Stop Switch and turn ...Our flagship Product : VIJAYCO® 5mm Hi Speed Strapping Roll, 10000 Mtrs = 10 kms on a single Paper Core

VIJAYCO® 5mm Hi-Speed Strapping Roll – 10,000 Meters Product Code: 05-47-N-10000-100-10 Category: PP Strapping Rolls Brand: VIJAYCO® Availability: On request (MOQ: 100 Rolls) Product Overview VIJAYCO® 5mm Hi-Speed Strapping Roll is our flagship ...